CNC Systems & Process Development

Concealed Mortise & Tenon Joinery System for Butt Joint Casework

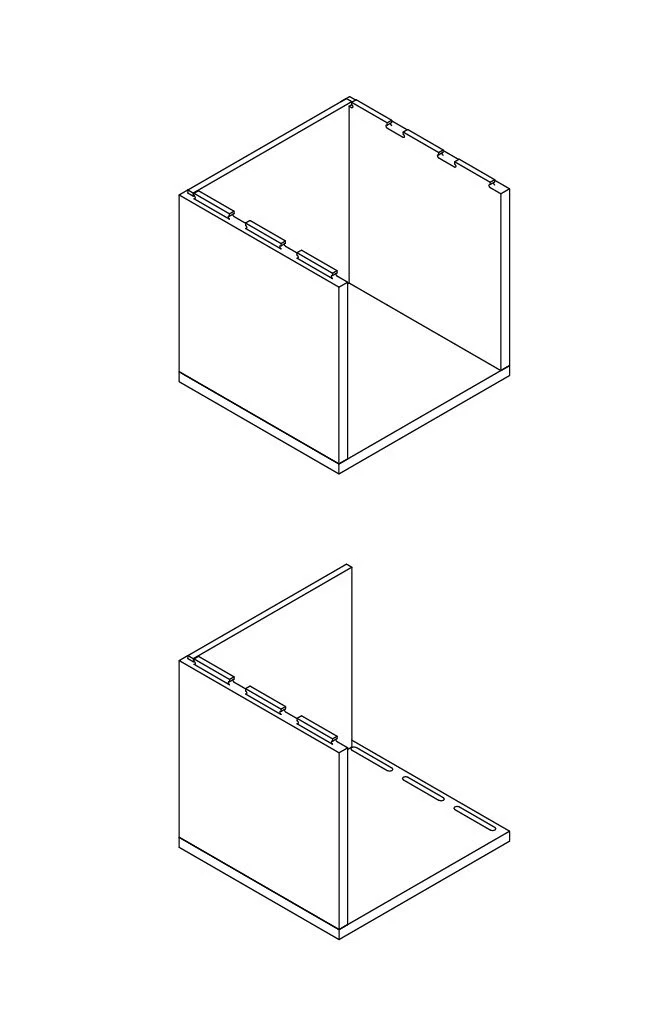

Scalable CNC joinery system developed for solid wood butt-joint casework, replacing manual Domino-based construction across all case sizes. The system uses CNC-milled integral tenons and mortises, including an undercut tenon strategy that allows all interior features to be machined in a single orientation while maintaining clean exterior geometry. Designed for repeatable production, strength, and efficiency across a wide range of cabinet scales.

Developed a CNC-native joinery system to replace manual Domino-based case construction, enabling consistent production across solid wood cases ranging from small furniture pieces to large architectural credenzas.

Re-engineered butt-joint case geometry around machining constraints, allowing all interior features and joinery to be milled in a single orientation without flip operations.

Designed integral tenon-and-mortise geometry, including an undercut tenon strategy, to maintain clean exterior faces while supporting efficient CNC workflows.

Applied DFMA principles to improve repeatability, reduce manual labor, and scale a traditionally hand-built process into a reliable digital fabrication system.

Established CNC processes that became the standard method for solid wood case construction across the product line.